Fields of Application

Meat

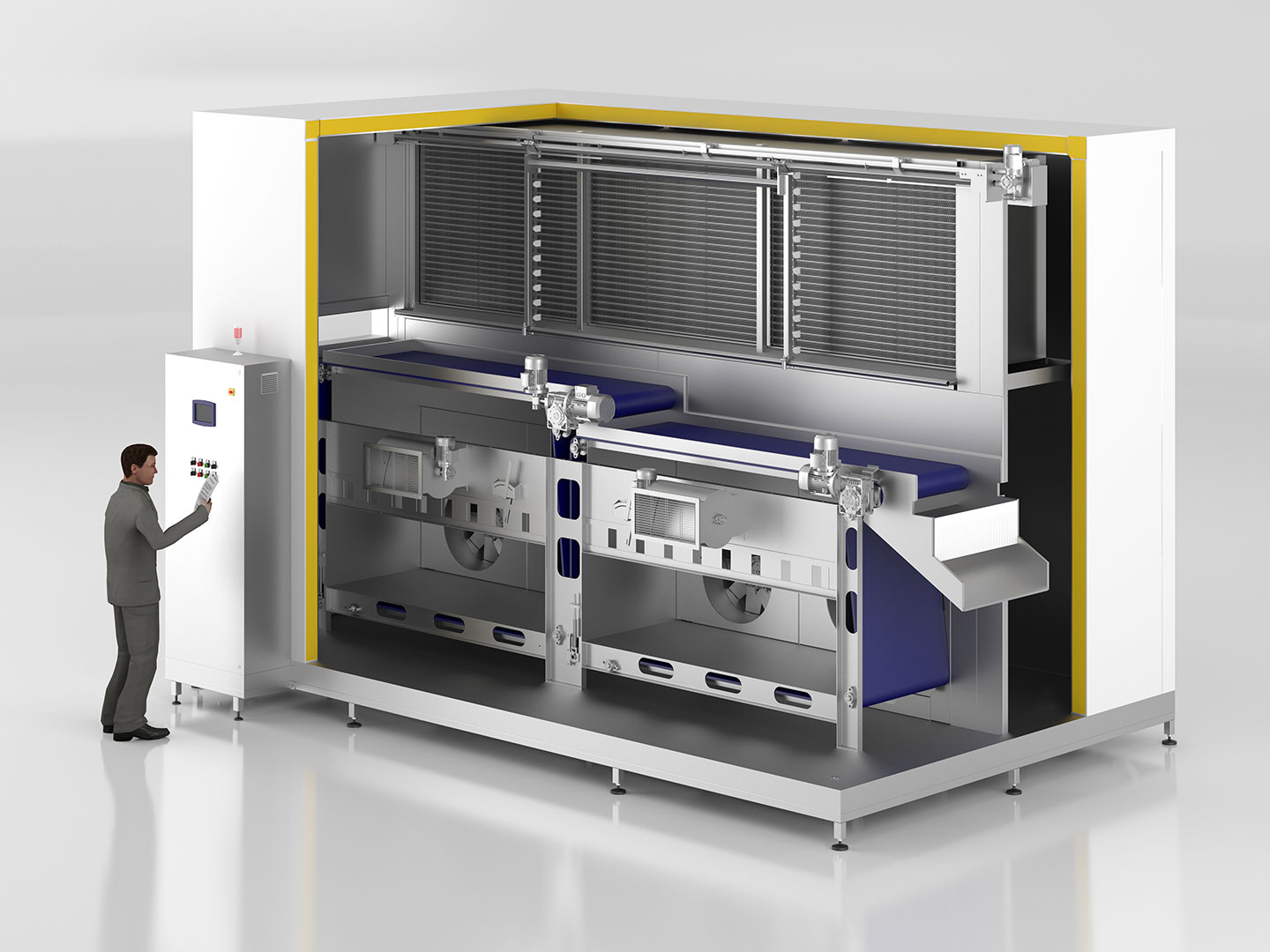

Floating Bed Tunnel

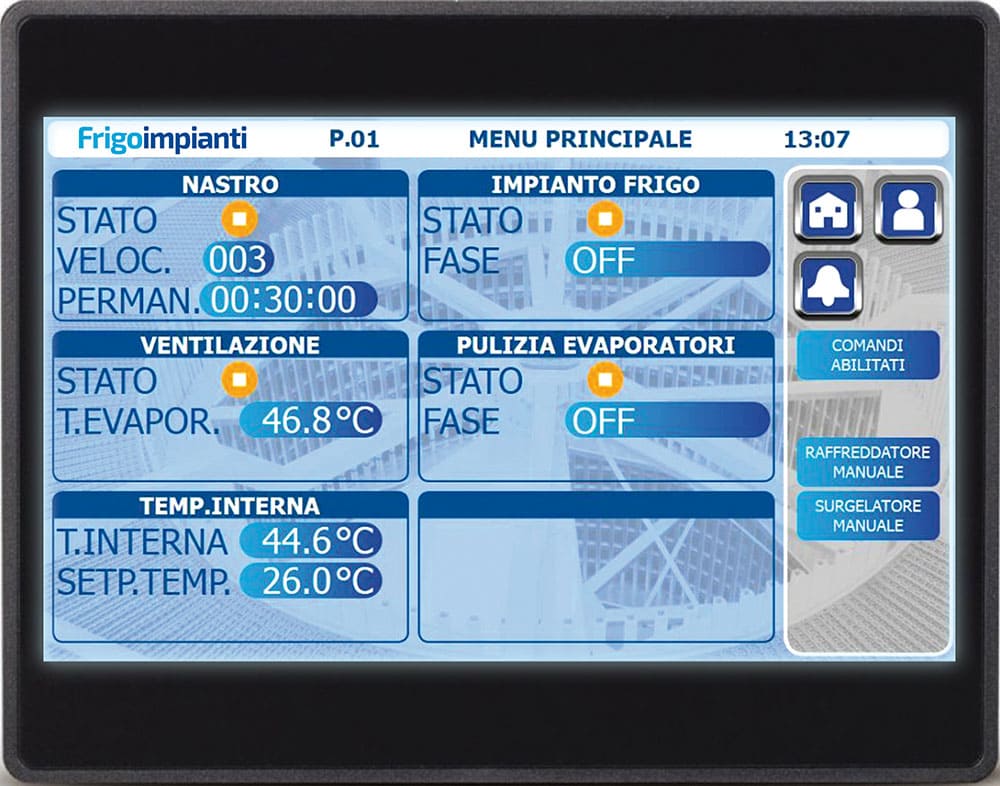

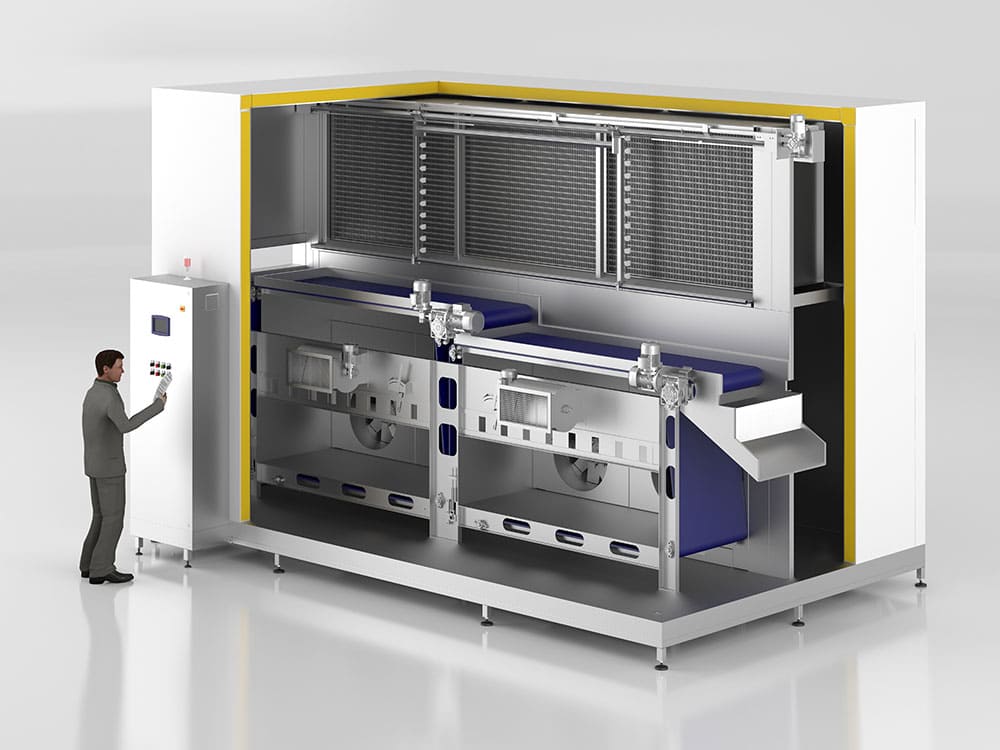

The Floating Bed Tunnel was designed to be used with small sized product processing lines such as: cherries, peas, tortellini, etc., which need to be frozen quickly in a uniform manner to guarantee complete conservation of their organoleptic characteristics and correct management during the packaging phase, thanks to the IQF freezing of the products.

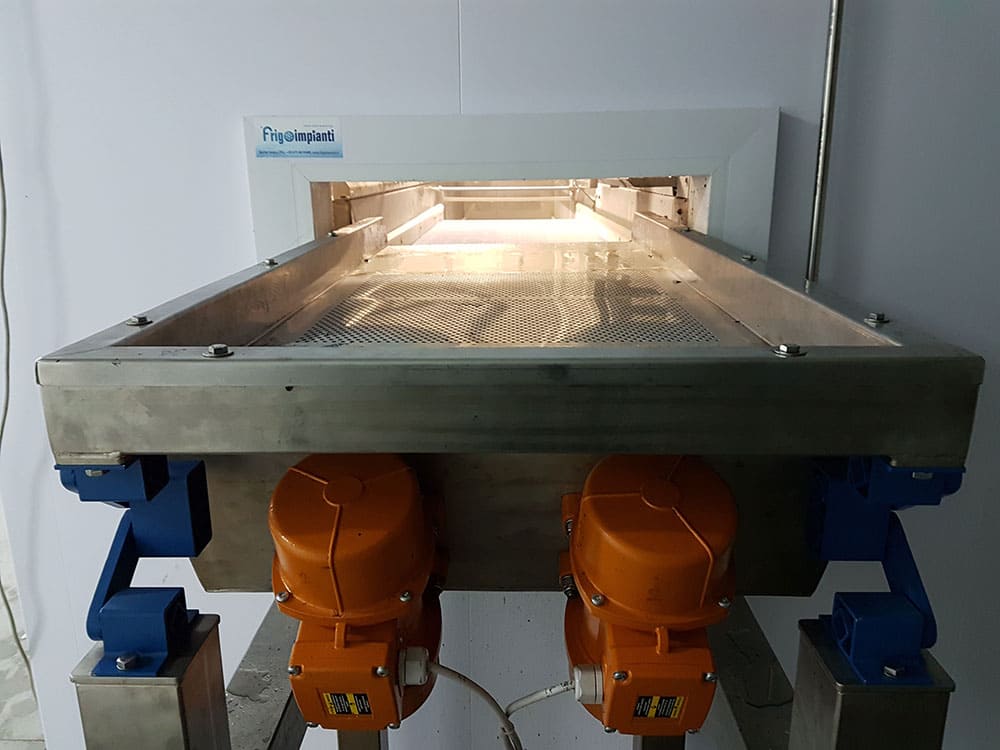

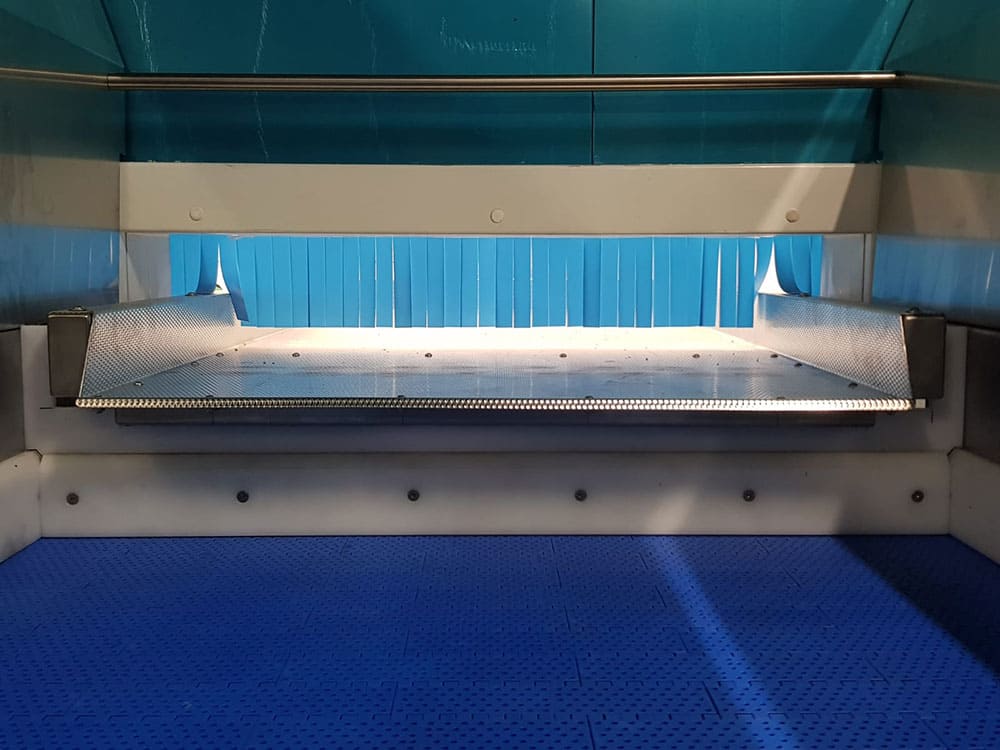

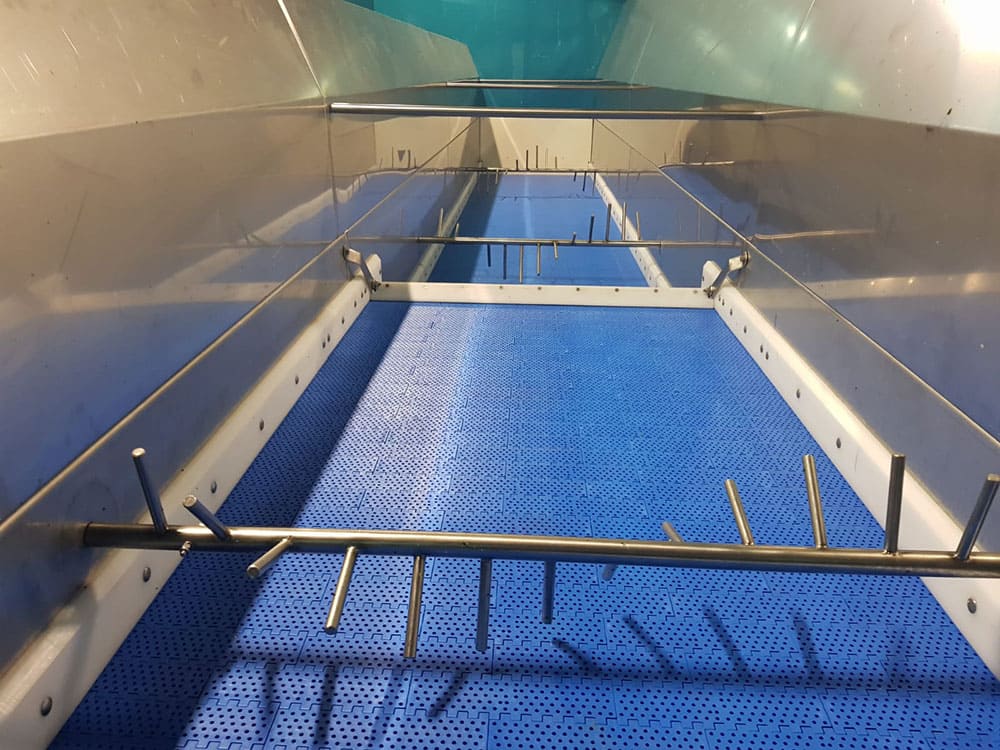

The tunnel structure can be composed of one or two conveyor belts positioned in series and two treatment zones: in the first one, the outer part of the product is frozen and thanks to the adjustable air speed, each piece is kept separate from the other. In the second zone, freezing takes place at the core of the product.

The advantages of the Frigo Impianti floating bed tunnel are:

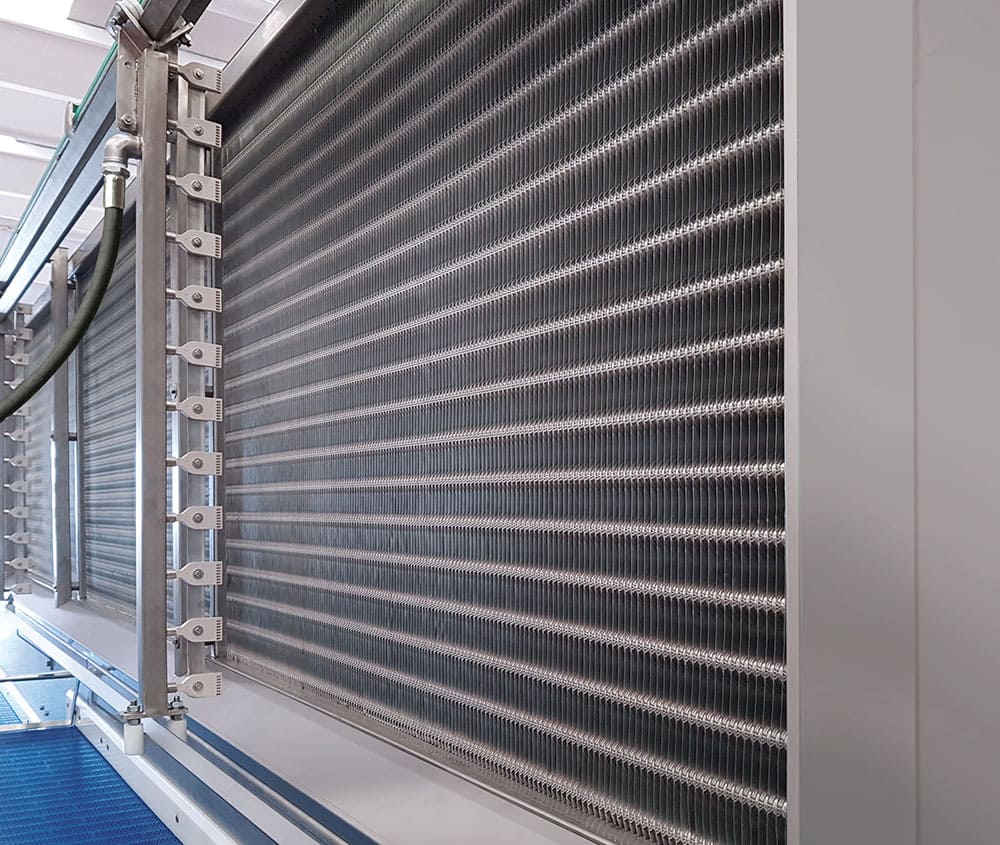

- Adjustable ventilation for handling any product, even the most delicate;

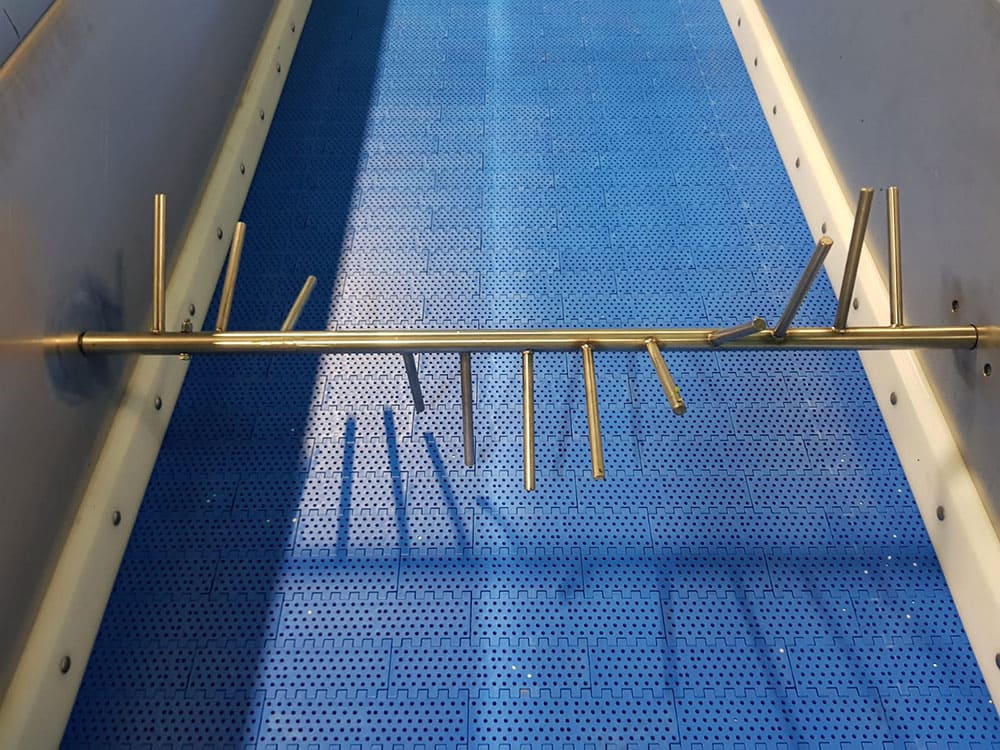

- Easily washable and inspectable structure;

- Can be installed anywhere as the structure is assembled directly by the customer;

- Maximum output in a small space;

- Production capacity from 250 to 4000 kg/h.