Fields of Application

Fish

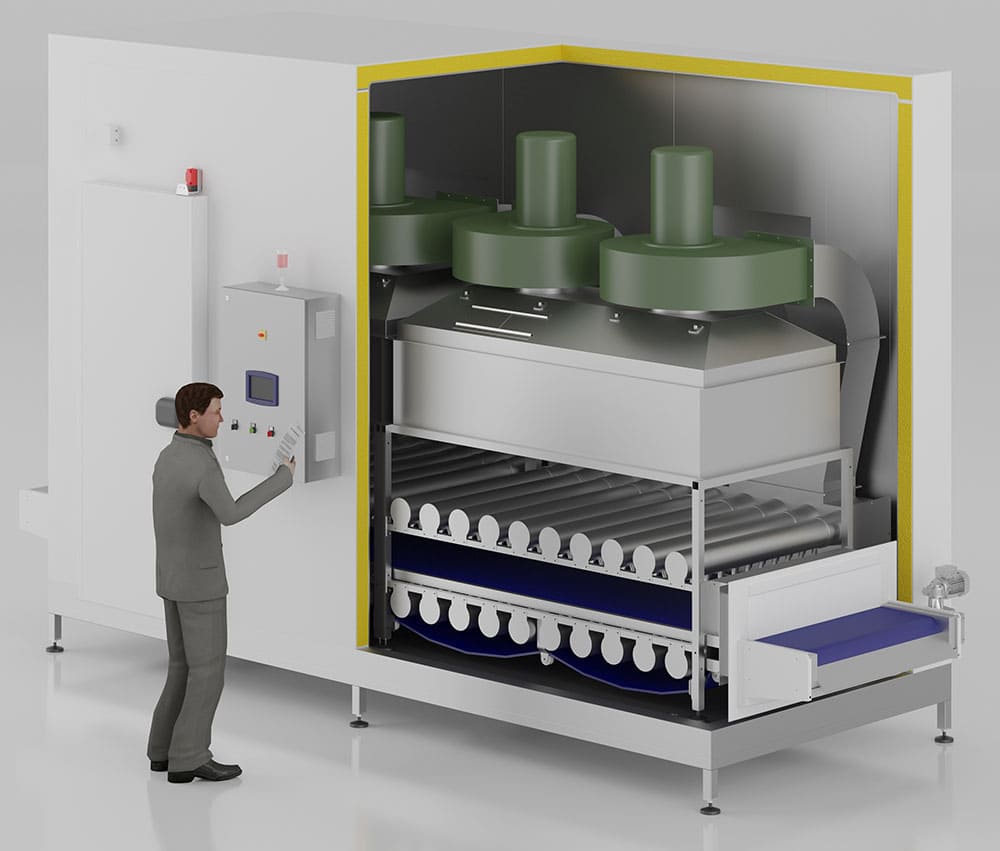

Bi-Flow Tunnel

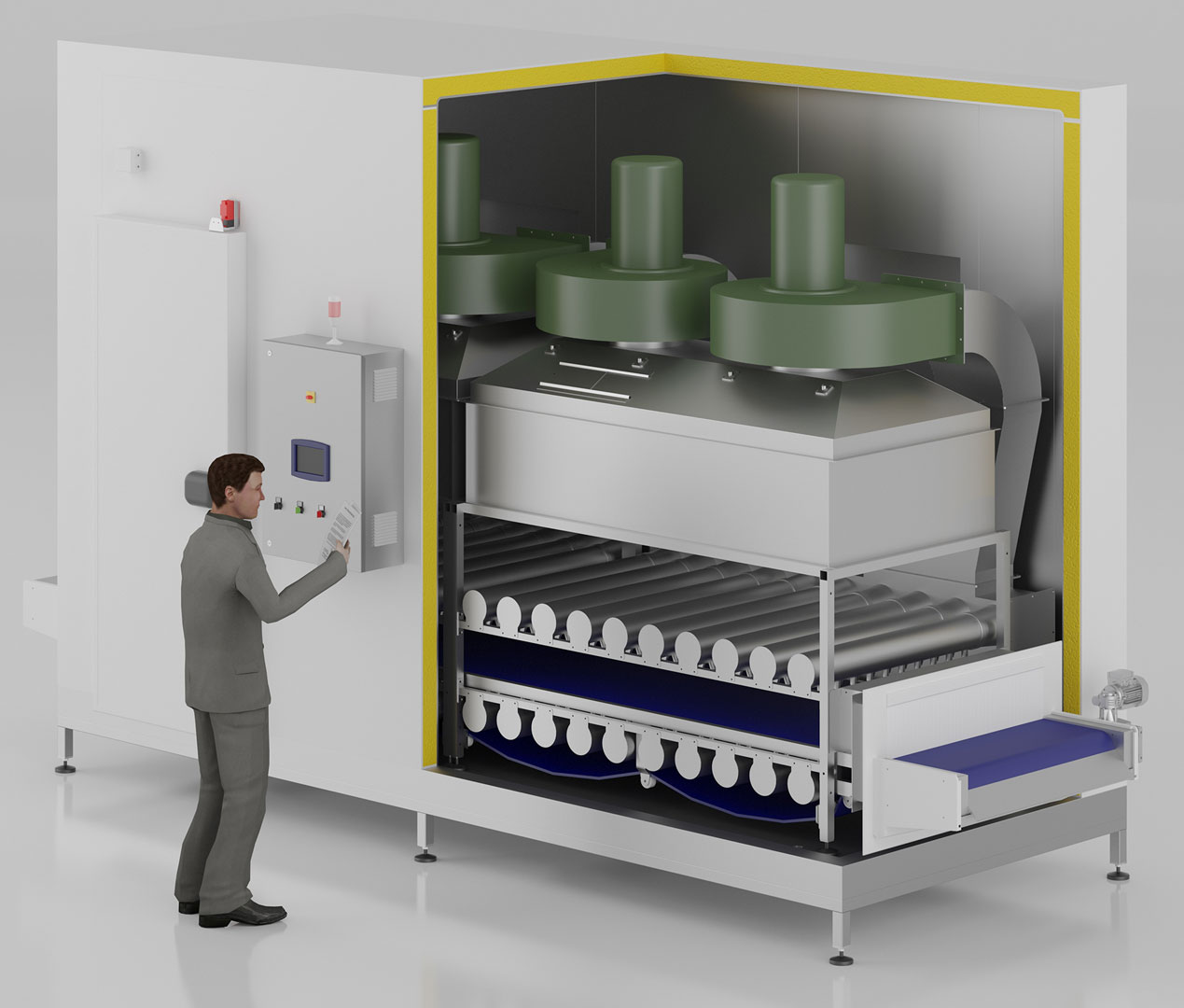

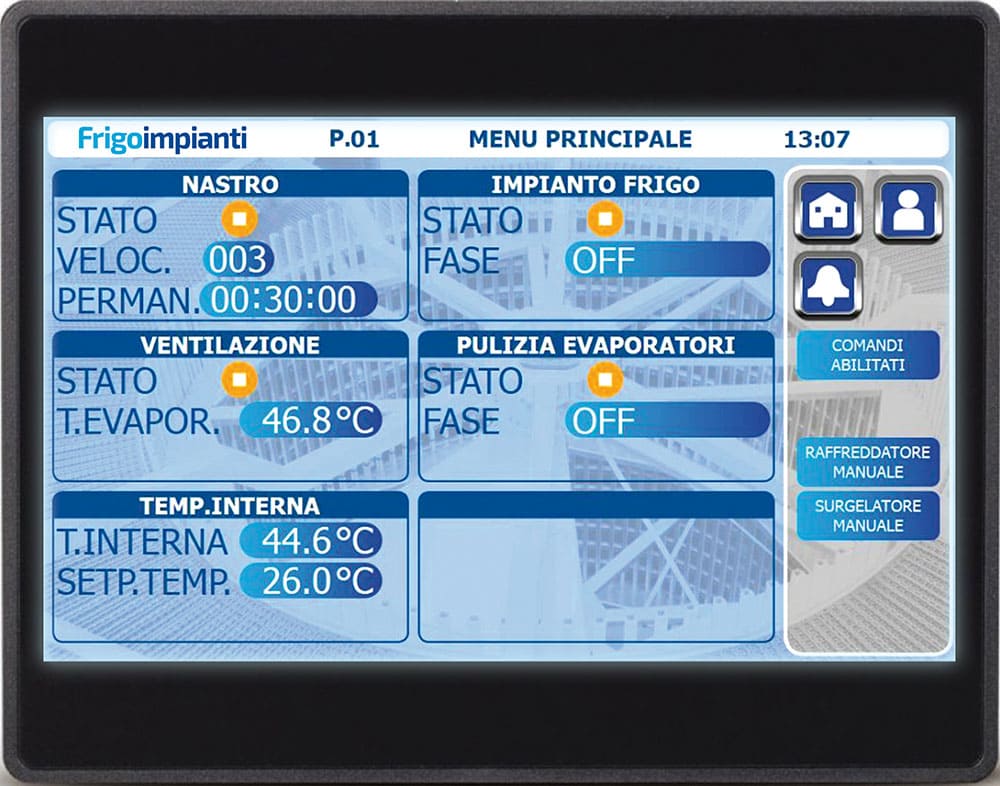

The Frigo Impianti Bi-Flow Tunnel is a very compact machine designed to be used in production lines that enable cooling and deep-freezing in very little time of all “thin and flat” products that must remain immobile on the belt during processing, such as hamburgers, fish and meat fillets etc.

This machine is also ideal for the ‘surface hardening’ of a wide range of products that have undergone a syringing process, that are to be sliced or that are to be packed in Skin Pack and must not get deformed.

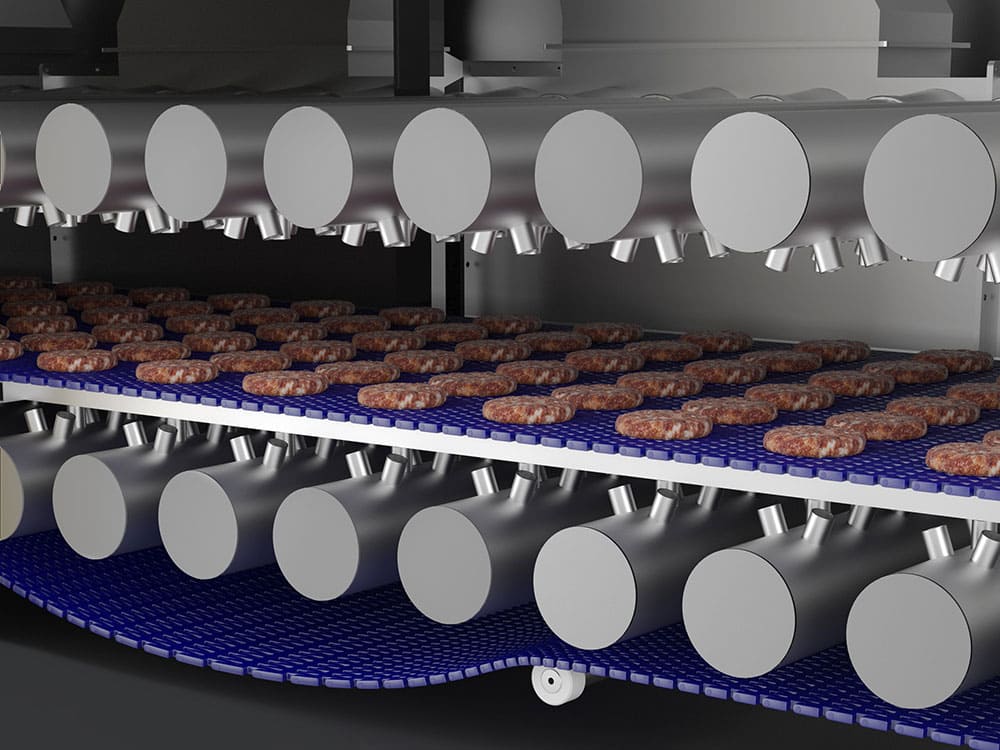

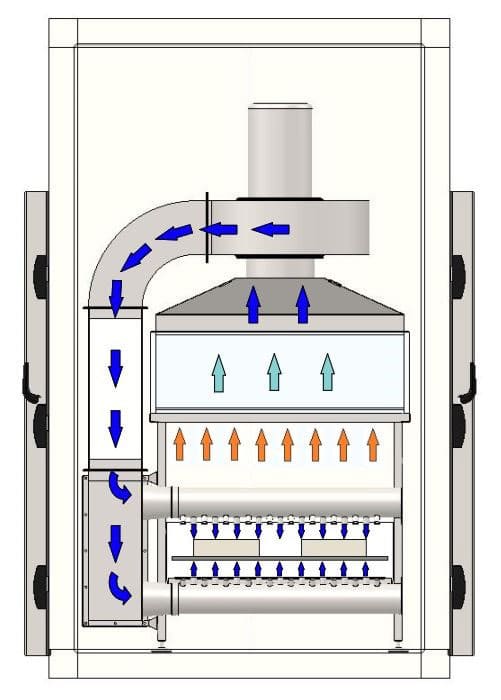

The characteristic of this machine is its ventilation system, which, through a series of bored-metal arms provided with directional conveyed air, placed above and below the belt, generate hundreds of high-speed air jets, which are equal and opposing, that cover the product uniformly, thus quickly cooling it and keeping it immobile during its whole passage.

The advantages of the Frigo Impianti Bi-Flow Tunnel are:

- Adaptability to multiple products and productions;

- Easily washable and inspectable structure;

- Belt designed to eliminate unwanted marking on processed products;

- Optimised ventilation to maximise output.

- The machine can be supplied with a plastic or stainless steel belt depending on the requirements of the processed product