Fields of Application

Pasta

Compact pasteuriser

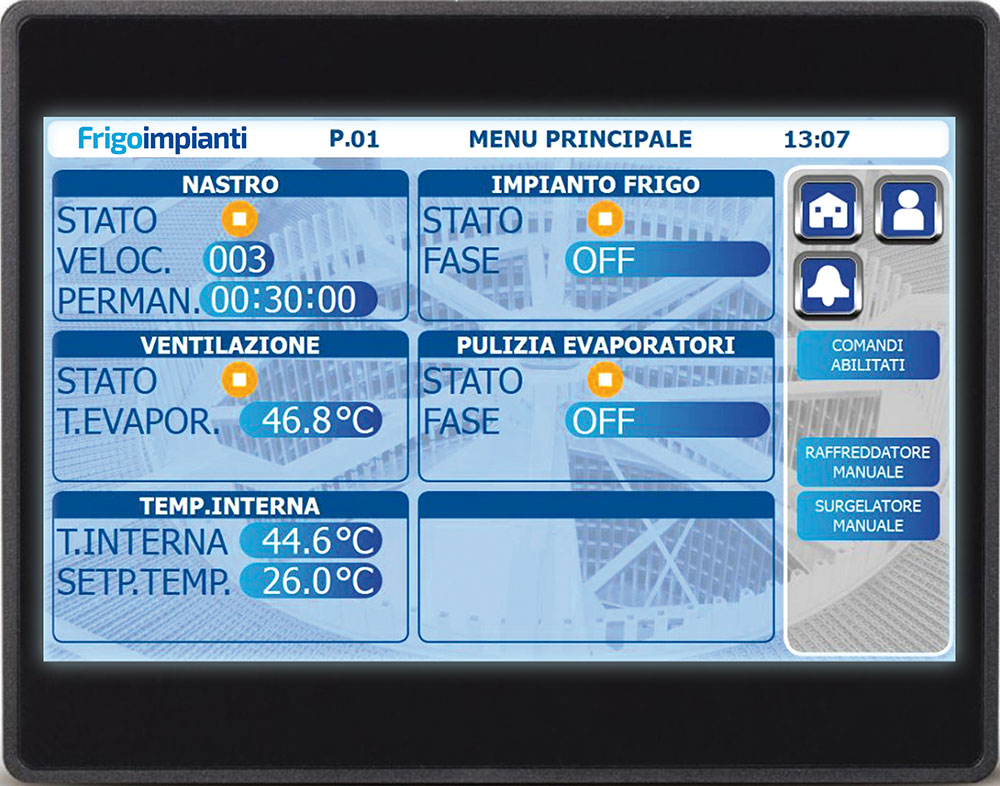

The ‘COMPACT’ Spiral Pasteuriser represents a new generation of pasteurisers for the treatment of fresh filled and non-filled pasta, equipped with a special technology that uses a ‘mix of heat and ventilated steam’ as a pasteurisation source. The machine is composed of a forced ventilation system for uniform product treatment and a special system, consisting of two steam heating coils and a mutually independent humidification circuit, that allows for temperature and humidity control inside the pasteurisation chamber.

This makes it possible to decide very precisely on the vapour coefficient with which one wishes to treat the product.

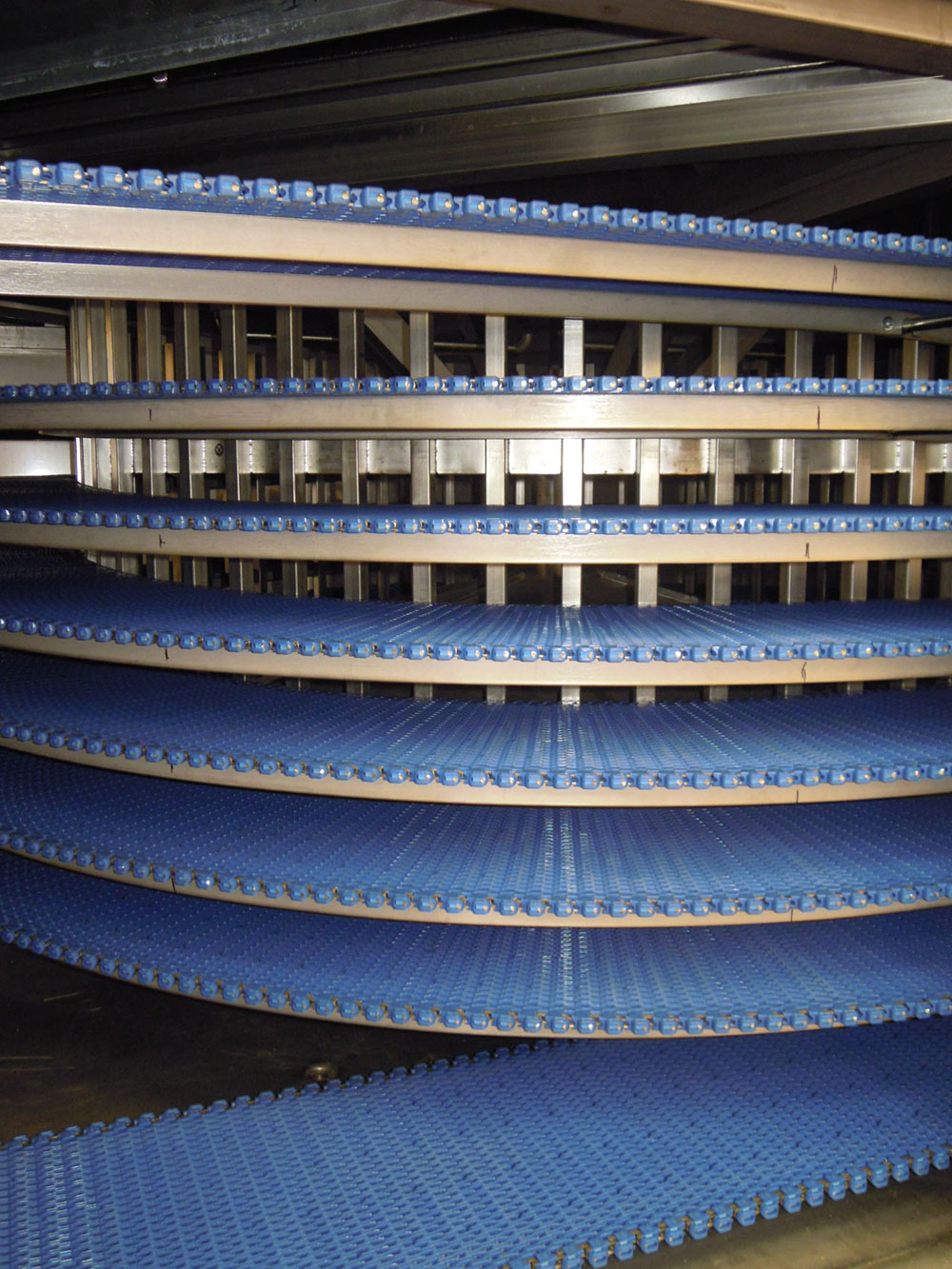

Thanks to its “spiral” transport system, this machine is able to treat large quantities of products in a very limited space. The end result of COMPACT use will be to obtain a quality product with a drier surface and a more ”natural” appearance, like before pasteurisation.

The advantages of the Frigo Impianti Compact Tunnel are:

- Absolute adaptability to any production line and space for installation;

- Easily washable and inspectable structure;

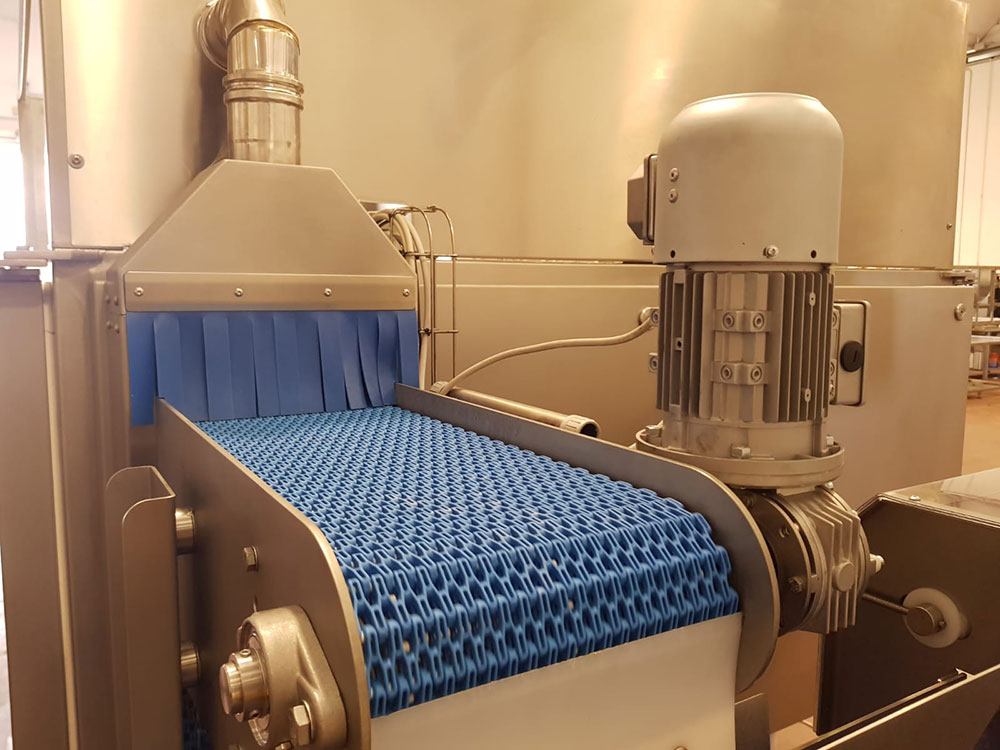

- Elimination of belt breakage by using the ‘Low tension belt system’;

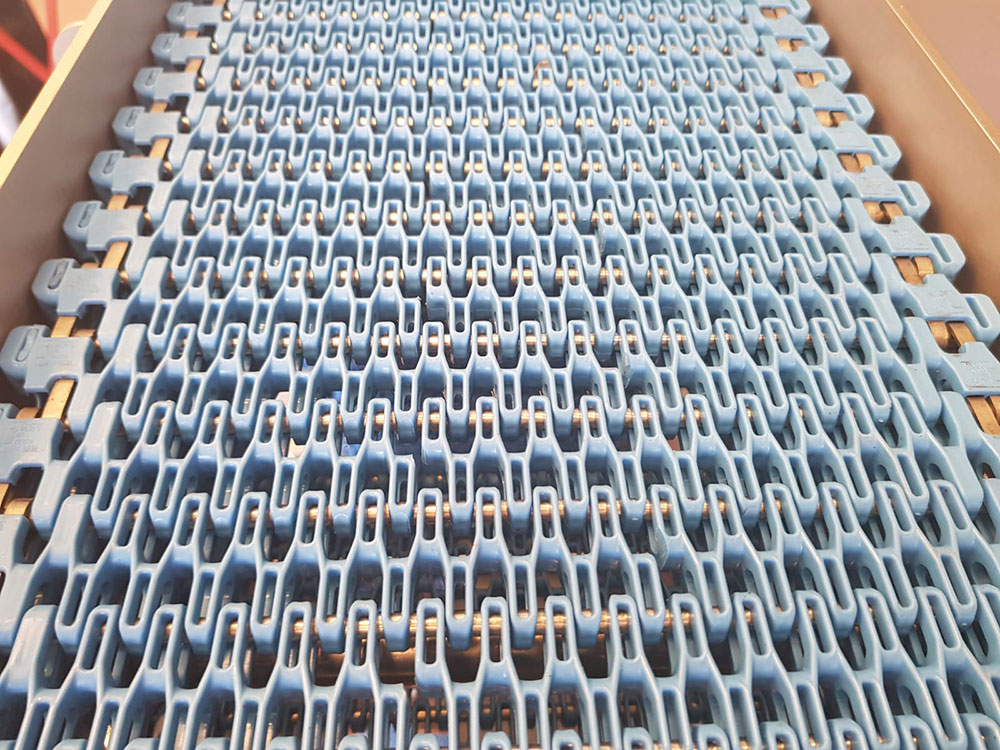

- Belt designed to eliminate unwanted marking on processed products;

- Easy to transport and install.