Fields of Application

Meat

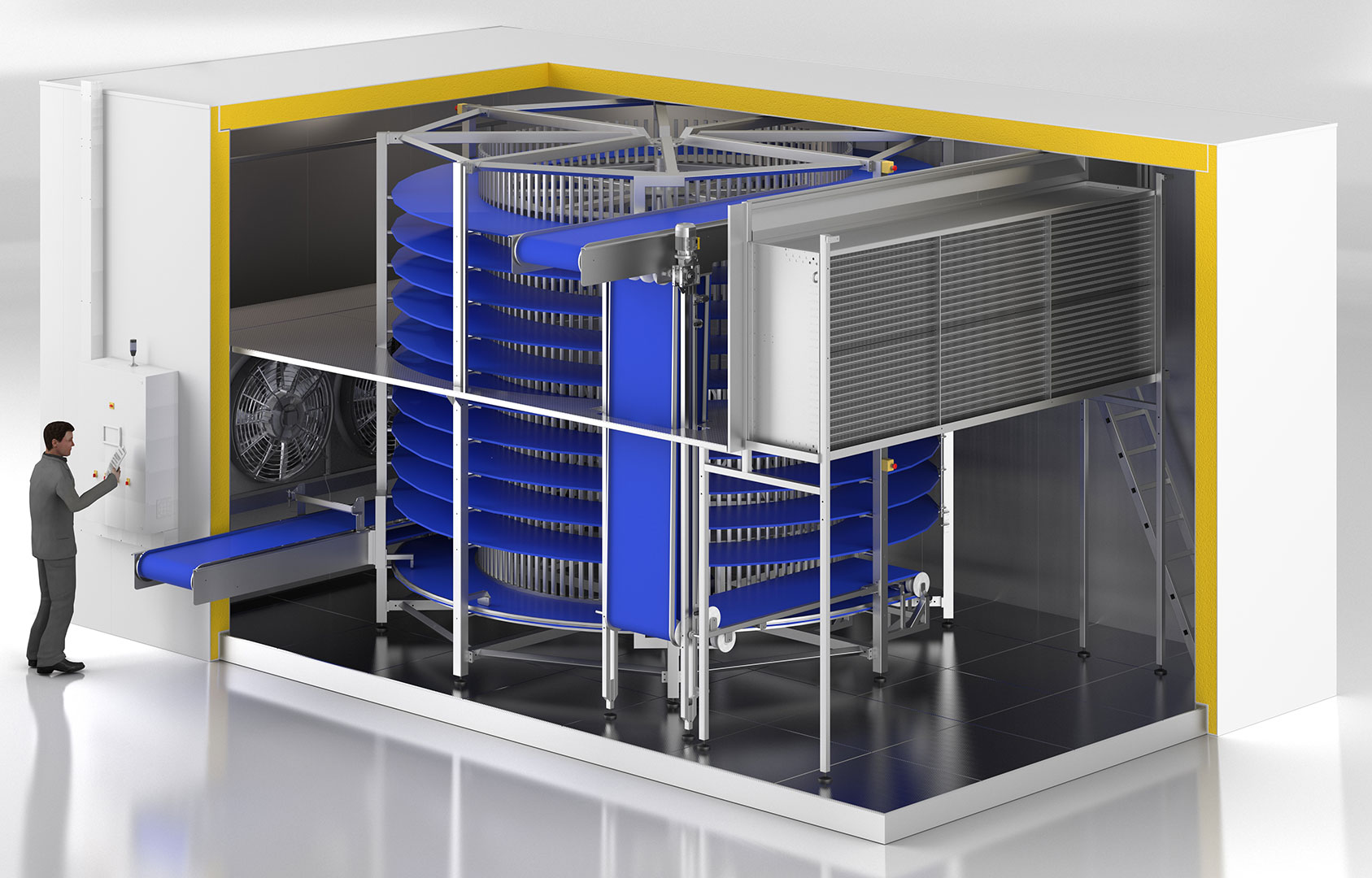

Spiral Tunnel

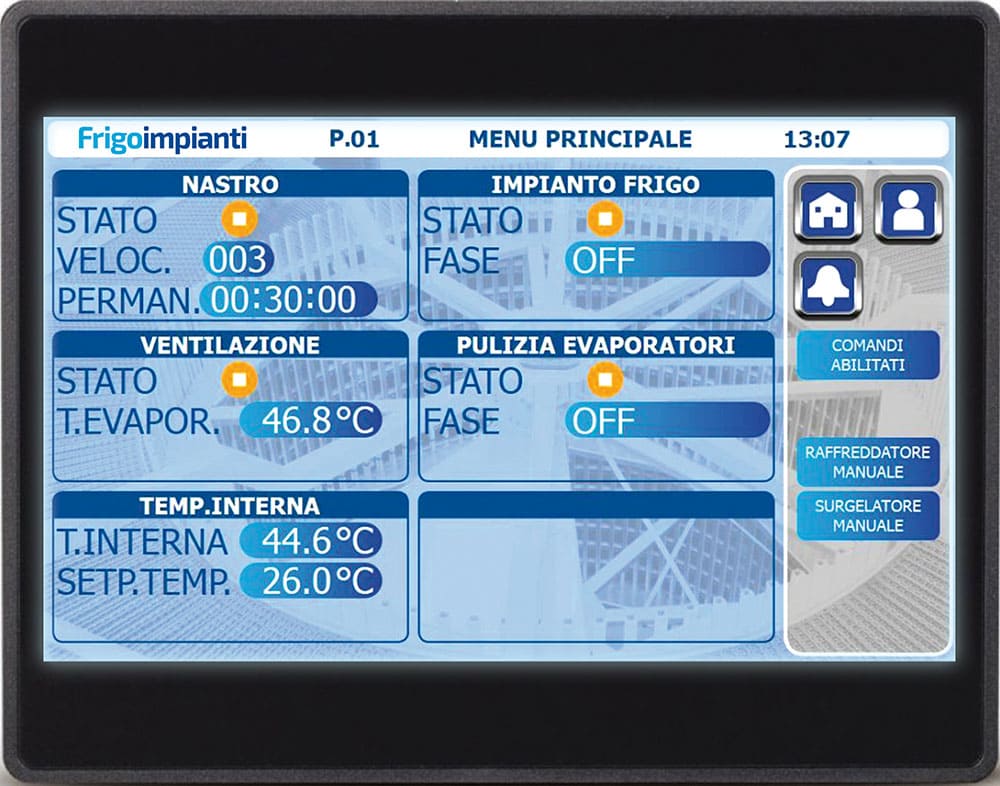

The Spiral Tunnel is a system designed to be used on medium and large production lines, which enables pasteurising, cooling or deep-freezing of all loose or packaged products that must remain immobile on the belt during processing, for example, hamburgers, pizzas, croissants, ready-made meals, etc.

They are very versatile machines that can adapt to any space and production need, as they are designed specifically for the customer and their specific production requirements; their configuration can range from single to double tower, ascending or descending, with inlet and outlet positioned according to the customer’s requirements.

The advantages of the Frigo Impianti Spiral Tunnel are:

- Absolute adaptability to any production line and space for installation;

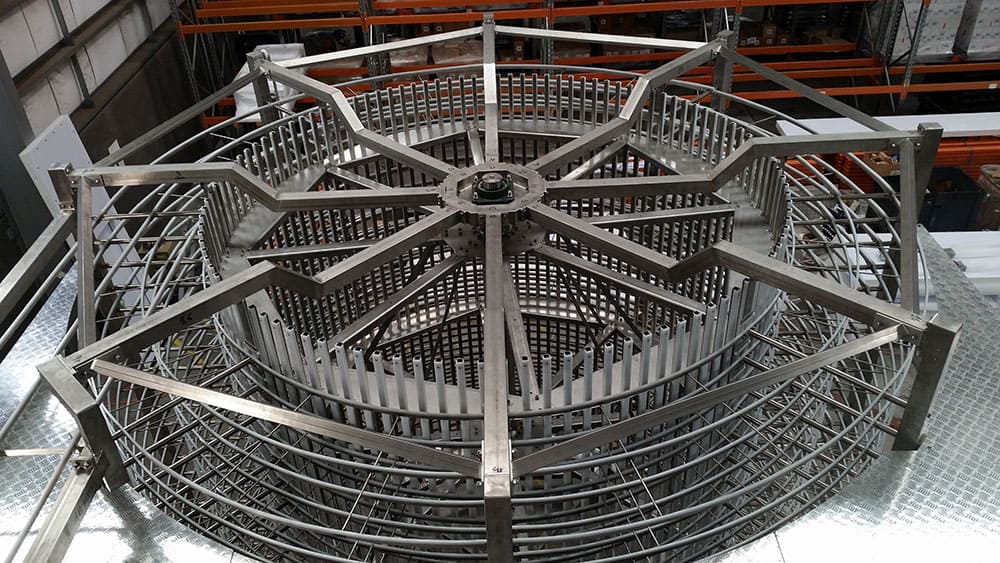

- Easily washable and inspectable structure;

- Elimination of belt breakage by using the “Low tension belt system”;

- Belt designed to eliminate unwanted marking on processed products;

- Optimised ventilation with dual counter-flow evaporators.